Add to Cart

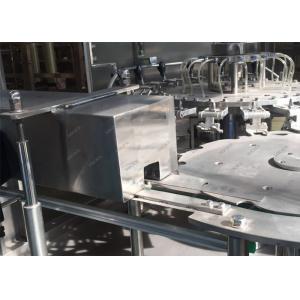

Manufacture Glass Bottle Beer BGF 40-40-12 for Beer Filling Machine

Description :.

1. Washing ---filling ---capping(crown cap) ---pasteurization tunnel ---bottle dryer ---label machine (one label / two label )---packing machine

2. This machine is my company's introduction of German technology, combined with the characteristics of beer production industry, designed to develop small scale beer filling equipment. The machine has excellent mechanical operation reliability, improved rinsing, filling, cover screwing, disinfection sterilization and other functions.

Feature:

1. The machine is widely used in the pharmaceutical, chemical, food, cosmetic and other industries adhesive labeling, round, cone bottle, square, flat, oval bottle or round bottle positioning double-sided labeling, batch number.

2. The design of the host computer absorbs the label transfer mode of the imported machine and solves the problem of instability of the general domestic label.

3. The machine can stand-alone operation and wiring production line

Specification:

Capacity: 1000-1500 bottle per hour(330 ml),1000-1200BPH(500 ml),800-1000 BPH(750 ml)

Applicable bottle : bottle height 200~350mm

Diameter : cc

Aseptic air consumption : 0.4m3/min(0.4~0.6Mpa)

CO2consumption:150g/100L

water consumption including :vacuum pump 0.15m3/h blowing 0.6m3/h

Details:

1, The rinsing part using high-strength stainless steel bottles of spring-loaded folders, to ensure a stable reversal of the glass bottles. The nozzle is a plum-like structure can wash every corner of the sidewall and bottom to make the bottle clean.

2, The Filling part with spring-type mechanical lifting equipment to upgrade glass bottles, large bearing support floundering in the vat and use of guide-rod in the orientation of the structure, there are pre-cover

features. Fill valve before filling have Double vacuum .

3, Using high-precision mechanical filling valve, with cylinder liquid level and the back pressure controlled by a variable signal proportional. Fast, stable, accurate, to be vacuum one at a time.

4, Stainless steel plunger and mechanical stirring gland-type magnetic reasonable cap to ensure that the gland is healthy and reliable. Hopper and the cap taking- cover, capping transmitted by magnetic. The capping is reliable and automatic unloading, reducing the rate of broken bottles.

5, the capping, use hot water bubble set to displace bottlenecks air, ensuring the oxygen content of less than 0.15mg / L.The caps are free from deforming,and can flow smoothly in large quantities during transmission.The capper has the function of automatic deloading,which helps lower the bottle breakage.

Beer spray sterilization tunnel AND Pasteurization system(such as follwing pictures)

Any need ,please directly contact me !